Excellent quality hotsell capillary quartz glass tube

Product Description

The largest part of our capillaries is produced with the redrawing method. During this process blanks (or so-called performs) are heated and drawn until they have reached the desired measure. The process is highly flexible and allows the production of prototypes or even large quantities on the same plants and under the same conditions. In addition to the redrawing method, some thick-walled capillaries may be directly drawn from the melt. In this process, however, there are limits to the precision and dimensions of the capillaries.

Subsequent In-house Processing

Apart from the production of capillaries, their processing is also one of our particular strengths. We utilize this strength for your individual requirements!

We offer various possibilities for further processing:

Cutting:

· Conventional cutting (score cutting)

· Laser cutting

· Conventional rotation cutting

· Abrasive cutting and sawing, with or without socketing

Drawing Tips:

· Computer-aided tip drawing in a hydrogen flame

· Production of micro-injection, patch and transfer pipettes on classic pipette pullers

Hot Forming:

· Specific bending and curving of capillaries up to 90°

· Crimping and pressing of capillaries in the rotational axis

· Deburring of cut edges (by fire polishing or glazing)

· One-sided or double-sided closing of end

· One-sided blowing of a sphere at the end of a capillary

· Constricting or tapering of the capillary profile

· Fusing with suitable metals in tube or wire form

· Laser micro-structuring (engraving/drilling/ablation/inscribing)

· Internal calibration (KPG process)

Cold forming:

· Surface grinding

· Faceting and grinding

· cylindrical grinding

· Bonding

· CNC processing

· Longitudinal cut by grinding or laser cutting

· internal drilling and grinding

Parameter of capillary quartz glass tube:

| Model | RE418 |

| Brand | Resucerial |

| Outer Diameter | 1.50-450mm |

| Material | high purity >99.95%(SiO2) |

| Wall Thickness | 0.30-20mm |

| Length | 10-4500mm |

| Shape | Straight, C, U,Round,Pear,spiral,domed, closed |

| Softening Point | 1680℃ |

| Annealing Point | 1210℃ |

| Strain Point | 1120℃ |

| Density | 2.2g/cm3 |

| Hardness | 5.5-6.50Mohs' |

| Design Tensile Strength | 4.80x 107 N/m^2 |

| Design Compressive Strength | 1.10x 109 N/m^2 |

Cofficient Of Thermal

Expansion(20-320℃) | 5.70x 10-7cm/cm.℃ |

| Thermal Conductivity(20℃) | 1.40W/m.℃ |

| Specific Heat(20℃) | 670J/Kg.℃ |

| Electrical Resistivity(350℃) | 7x 107ohm.cm |

| Dielectric Constant | 3.75 |

| Dielectric Strength | 5x107V/m |

Clear Fused Quartz Glass Tube

Chemical Composition |

AL | K | Na | Li | Ca | Mg | Cu | Mn | Pb | B | Ti |

20 | 3.5 | 3.5 | 1.0 | 2.0 | 0.5 | 0.3 | 0.5 | <0.01 | <0.2 | 2.0 |

| Dimensional Tolerance |

| RANGE OF OD | OD | WT | siding | OUT OF ROUND | BOW/1220MM |

| <6MM | ±2.0% | ±10% | 12% | 2.00% | 2.5MM |

| 6.0-15.00MM | ±1.25% | ±8% | 10% | 1.50% | 2.5MM |

| 15.0-20.0MM | ±1.25% | ±10% | 15% | 1.50% | 2.5MM |

| 20.0-25.0MM | ±1.25% | ±10% | 15% | 1.50% | 3.0MM |

| 25.0-30.0MM | ±1.35% | ±12% | 15% | 1.50% | 3.0MM |

| 30.0-80.0MM | ±1.5% | ±14% | 15% | 2.00% | 3.0MM |

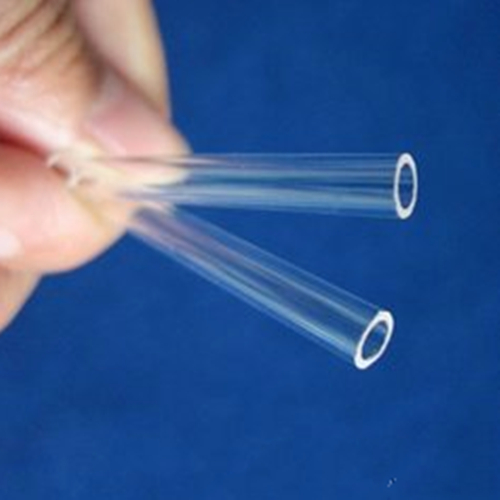

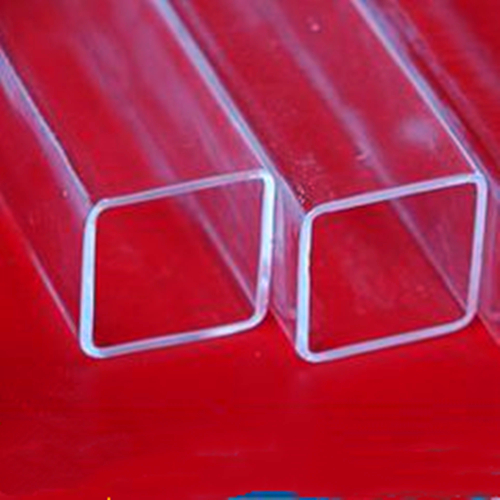

Photos of capillary quartz glass tube:

Samples:

Certification:

Production Process:

Packing:

Shipping:

Our Team:

Exhibition:

capillary quartz glass tube